If you’ve ever worked with copper fittings, you may have wondered why they need to be cleaned before soldering or brazing. It’s a common question that many people have, and today we’re going to dive into the answer. So, why are copper fittings cleaned before soldering or brazing? Let’s find out.

When it comes to joining copper fittings, cleanliness is key. Before you can apply heat and create a strong bond, you need to ensure that the surfaces are free from any dirt, grease, or oxidation. This is because these contaminants can interfere with the solder or brazing material, preventing it from properly adhering to the copper. To achieve a strong and reliable joint, it’s crucial to remove any impurities and create a clean surface for the solder or brazing material to flow and bond with the copper fitting. So, let’s explore the reasons behind the importance of cleaning copper fittings before soldering or brazing.

Now that we understand the importance of cleanliness when it comes to soldering or brazing copper fittings, let’s delve into the specific reasons why cleaning is necessary. First and foremost, cleaning the fittings helps to remove any dirt or grease that may be present on the surface. This is important because dirt and grease can act as a barrier, preventing the solder or brazing material from properly adhering to the copper. By cleaning the fittings, you create a clean and smooth surface that allows the solder or brazing material to flow and bond effectively.

In addition to dirt and grease, oxidation is another common issue that needs to be addressed before soldering or brazing copper fittings. Over time, copper can develop a layer of oxide on its surface, which can hinder the bonding process. By cleaning the fittings, you remove this oxide layer and expose the fresh, clean copper underneath. This ensures that the solder or brazing material can make direct contact with the copper, leading to a strong and reliable joint.

In conclusion, cleaning copper fittings before soldering or brazing is crucial for achieving strong and reliable joints. By removing dirt, grease, and oxidation, you create a clean surface that allows the solder or brazing material to flow and bond effectively with the copper. So, the next time you’re getting ready to work with copper fittings, make sure to prioritize the cleaning step for optimal results.

Contents

Why Are Copper Fittings Cleaned Before Soldering or Brazing?

When it comes to soldering or brazing copper fittings, proper cleaning is a crucial step that should never be overlooked. Copper fittings are commonly used in plumbing and HVAC systems due to their excellent thermal conductivity and corrosion resistance. However, before joining copper fittings together, it is important to thoroughly clean them to ensure a strong and reliable connection. In this article, we will explore why copper fittings need to be cleaned before soldering or brazing and the benefits it brings.

The Importance of Cleaning Copper Fittings

1. Removal of Oxidation: Over time, copper fittings can develop a thin layer of oxide on their surface, which can hinder the solder or brazing material from properly adhering to the fitting. By cleaning the fittings, this layer of oxide is removed, allowing for better bonding and ensuring a leak-free joint.

2. Removal of Contaminants: Copper fittings may also accumulate dirt, grease, or other contaminants during storage or handling. These contaminants can interfere with the solder or brazing process, leading to weak joints or even failure. Cleaning the fittings helps eliminate these contaminants, creating a clean surface for optimal solder or brazing adhesion.

The Cleaning Process

1. Mechanical Cleaning: The first step in cleaning copper fittings involves mechanically removing any visible dirt or debris. This can be done using a wire brush or abrasive pad to scrub the fittings. It is important to pay attention to hard-to-reach areas and ensure that all surfaces are thoroughly cleaned.

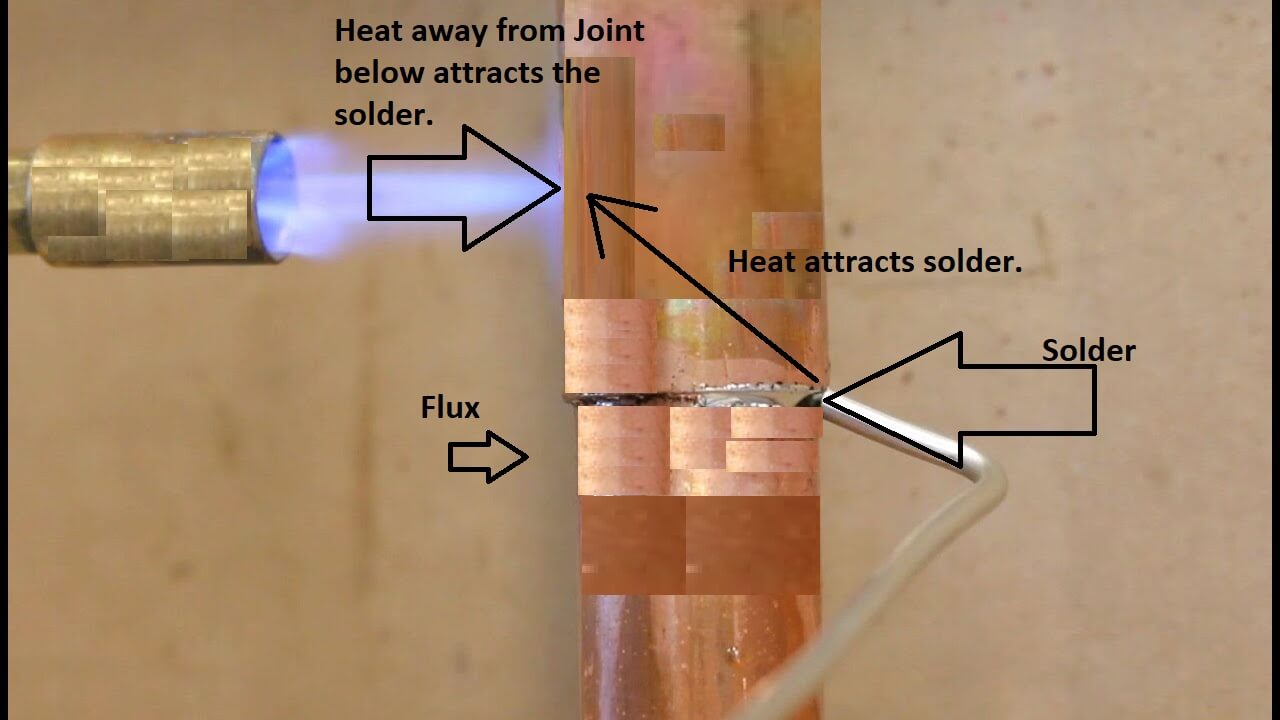

2. Chemical Cleaning: After the initial mechanical cleaning, a chemical cleaning solution is applied to further remove oxidation and contaminants. Commonly used solutions include flux, an acidic paste that helps dissolve the oxide layer, and a solvent to remove any remaining contaminants. The fittings are immersed in the solution or the solution is applied using a brush or cloth, depending on the size and shape of the fittings.

3. Rinsing: Once the chemical cleaning is complete, the fittings should be thoroughly rinsed with water to remove any residue from the cleaning solution. This step is important to ensure that no harmful chemicals remain on the surface of the fittings, which could potentially affect the solder or brazing process.

4. Drying: After rinsing, it is crucial to allow the fittings to dry completely before proceeding with soldering or brazing. Moisture can interfere with the bonding process and weaken the joint. Ensure that the fittings are dried in a clean and dust-free environment to prevent any contamination.

By following these cleaning steps, you can ensure that your copper fittings are ready for soldering or brazing, resulting in strong, durable, and leak-free connections. Properly cleaned fittings also contribute to the overall longevity and performance of the plumbing or HVAC system.

The Benefits of Cleaning Copper Fittings

1. Stronger Joints: Cleaned copper fittings provide a clean and smooth surface for the solder or brazing material to adhere to, resulting in stronger joints. This is crucial for maintaining the integrity of the plumbing or HVAC system and preventing leaks.

2. Improved Heat Transfer: When copper fittings are cleaned, the thermal conductivity of the material is optimized. This allows for efficient heat transfer, which is particularly important in HVAC systems or applications where heat dissipation is critical.

3. Reduced Risk of Contamination: By cleaning copper fittings, you minimize the risk of contamination from dirt, grease, or other substances. Contaminants can negatively impact the performance of the system and compromise its overall efficiency. Cleaning ensures that the system operates at its full potential.

Conclusion

In conclusion, cleaning copper fittings before soldering or brazing is essential for achieving strong, reliable, and leak-free connections. The process involves mechanical and chemical cleaning to remove oxidation and contaminants, followed by thorough rinsing and drying. Cleaned fittings provide numerous benefits, including stronger joints, improved heat transfer, and reduced risk of contamination. By following proper cleaning procedures, you can ensure the longevity and performance of your plumbing or HVAC system.

Key Takeaways: Why are Copper Fittings Cleaned before Soldering or Brazing?

- Copper fittings are cleaned before soldering or brazing to remove dirt, grease, and oxidation.

- Cleaning ensures a strong bond between the fitting and the solder or brazing material.

- Dirt and grease can affect the flow of solder or brazing material, leading to weak connections.

- Oxidation on copper surfaces can prevent proper adhesion of the solder or brazing material.

- Cleaning also helps to remove any contaminants that could cause leaks or other issues.

Frequently Asked Questions

When it comes to soldering or brazing copper fittings, it is crucial to clean them beforehand. This process may seem like an extra step, but it serves an important purpose in ensuring a successful and secure joint. In this section, we will address some common questions related to why copper fittings should be cleaned before soldering or brazing.

Question 1: What happens if copper fittings are not cleaned before soldering or brazing?

Answer: If copper fittings are not properly cleaned before soldering or brazing, a few issues may arise. Firstly, any residual dirt, grease, or oxidation on the surface of the fitting can prevent the solder or brazing material from adhering properly. This can result in weak joints that may leak or fail over time. Additionally, contaminants on the fitting can lead to poor heat transfer during the soldering or brazing process, making it difficult to achieve the desired temperature for a successful joint.

Furthermore, when copper fittings are not cleaned, the presence of impurities can cause oxidation and corrosion to occur over time. This can weaken the fitting and compromise its integrity, leading to potential leaks or system failures.

Question 2: How should copper fittings be cleaned before soldering or brazing?

Answer: To ensure proper cleaning of copper fittings before soldering or brazing, it is recommended to follow a few steps. Firstly, the fittings should be visually inspected for any visible dirt, grease, or oxidation. These contaminants can be removed using a wire brush or emery cloth, gently scrubbing the surface until it appears clean and shiny.

Next, it is important to use a suitable cleaning agent specifically designed for copper. This can be in the form of a commercial cleaner, flux, or a mixture of vinegar and water. The cleaning agent should be applied to the fitting and allowed to sit for a few minutes to dissolve any remaining impurities. Afterward, the fitting should be rinsed thoroughly with water to remove any residue from the cleaning process.

Question 3: Can I use sandpaper to clean copper fittings before soldering or brazing?

Answer: While sandpaper may seem like a viable option for cleaning copper fittings, it is generally not recommended. Sandpaper can leave behind tiny abrasive particles that can scratch the surface of the fitting, creating rough spots. These rough spots can hinder the proper adhesion of the solder or brazing material, resulting in weak joints. It is best to use a wire brush or emery cloth, as they are specifically designed for cleaning copper without causing damage.

If sanding is absolutely necessary, choose a fine-grit sandpaper and be cautious not to apply excessive pressure. After sanding, make sure to thoroughly clean the fitting to remove any sanding residue before proceeding with soldering or brazing.

Question 4: Are there any alternatives to cleaning copper fittings before soldering or brazing?

Answer: Cleaning copper fittings before soldering or brazing is a critical step that should not be skipped. However, if you are faced with a situation where cleaning is not feasible, there are alternative methods to improve the joint’s integrity. One option is to use a flux with cleaning properties, as it can help remove light contaminants and oxidation during the soldering or brazing process. Additionally, applying more heat during the soldering or brazing process can help burn off some impurities, although this may not be as effective as proper cleaning.

It is important to note that these alternatives may not provide the same level of reliability as thorough cleaning. Therefore, it is highly recommended to prioritize proper cleaning before soldering or brazing copper fittings.

Question 5: Can I reuse copper fittings without cleaning them again?

Answer: It is generally advised to clean copper fittings before every soldering or brazing operation, even if they have been previously cleaned. Over time, copper fittings can accumulate dirt, grease, or oxidation, especially if they have been stored or exposed to environmental elements. Reusing fittings without cleaning them again can compromise the quality of the joint and increase the risk of leaks or failures. To ensure the best results, it is recommended to clean copper fittings before each soldering or brazing session.

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

Final Thoughts

After delving into the topic of why copper fittings are cleaned before soldering or brazing, it is clear that this crucial step is not to be overlooked. Cleaning copper fittings before soldering or brazing ensures optimal performance and longevity of the joint. By removing dirt, grease, and oxidation, the copper surfaces can bond more effectively, leading to stronger connections and minimizing the risk of leaks or failures.

Additionally, cleaning copper fittings eliminates any potential contaminants that could hinder the soldering or brazing process. Flux, which is used to promote the flow of solder and prevent oxidation during heating, requires a clean surface to adhere to. Without proper cleaning, flux may not adhere properly, compromising the integrity of the joint. By taking the time to clean copper fittings before soldering or brazing, professionals can ensure a successful and durable outcome.

In conclusion, the importance of cleaning copper fittings before soldering or brazing cannot be overstated. By adhering to this essential step, professionals can achieve strong, reliable connections that will withstand the test of time. So, whether you’re a seasoned plumber or a DIY enthusiast, remember to prioritize cleanliness in your soldering or brazing projects for optimal results.